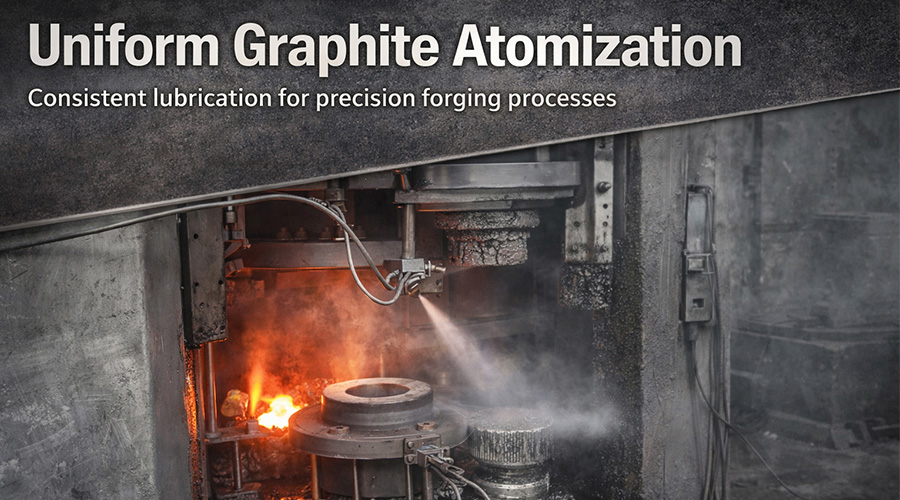

Forging die refers to a tool that can form blanks into die forgings. Forging die is the key process equipment necessary in the production of die forgings, and it is a tool that needs to be used in every stroke of the equipment. It plays a pivotal role in the production of die forgings. Die wear is common during the forging process. Die wear mainly refers to the relative movement between the two parts in the friction pair. In addition to observing the general laws of the wear of mechanical parts, the wear of the forging die also has its particularity due to its harsh working environment. After the forgings are heated by the heating furnace, they need to be forged with a press, because the hardness of some of the oxide scales is relatively high and the distribution is uneven. At this time, the harder oxide scale will accelerate the wear of the mold, which virtually increases the cost of the enterprise. However, customizing a mold is relatively expensive, not to mention that it is common for the mold to be worn during the forging process. Therefore, many forging plants have been using various methods to remove the oxide scale on the surface of the forging to reduce mold wear. At present, the most commonly used method of forging oxide scale treatment is to use the principle of high-pressure water descaling to remove, and it is also the most feasible method for oxide scale removal at present. The oxide scale can be treated by the high-pressure water generated by the high-pressure pump. The oxide scale cleaning process is very fast, the temperature is very little, and the cleaning is very clean, so that the oxide scale is reduced during the forging process, and the damage caused by the excessively hard oxide scale is avoided. Unnecessary wear of the mold reduces the service life, which increases the service life of the mold and at the same time improves work efficiency. Therefore, the use of a forged oxide scale cleaning machine can not only improve the surface quality of forgings, but also increase production efficiency. And it can greatly reduce the mold wear caused by oxide scale, so the use of forging oxide scale cleaning machine to remove oxide scale before forging is a process worthy of promotion and publicity.

français

français Deutsch

Deutsch русский

русский italiano

italiano español

español 日本語

日本語 Türkçe

Türkçe Tiếng việt

Tiếng việt Indonesia

Indonesia

IPv6 network supported

IPv6 network supported