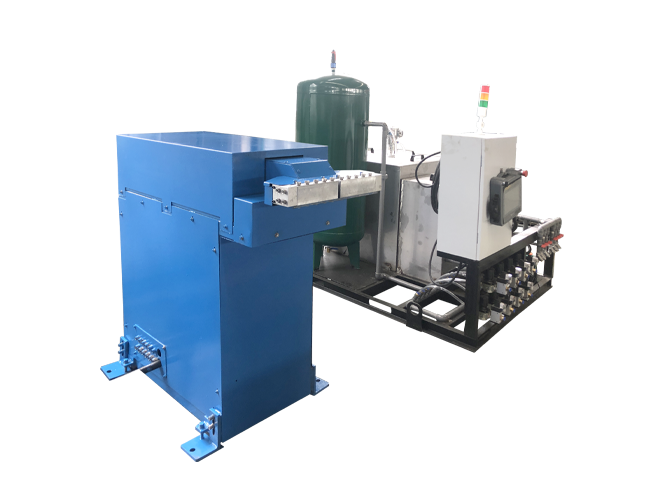

Automatic graphite spraying equipment can be used in forging production such as free forging, die forging, ring rolling process, metal die pressing, hot extrusion processing (aluminum, copper and other non-ferrous metals), and can be used with forging supporting equipment such as electric screw press, friction press, high-energy press, direct-drive press, hot die forging, precision forging machine, electro-hydraulic hammer, punch press and oil press. Automatic lubrication system can be applied to forging products such as gears, shafts, bolts, flanges, hinges, crankshafts, connecting rods and ball heads.

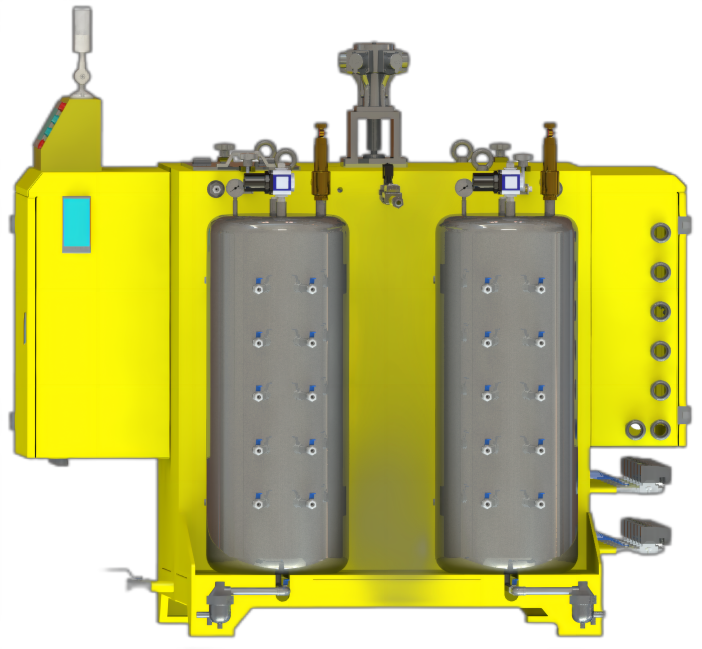

Item NO.:

DSKL-FL-01Market Price:

$10000Product Origin:

ChinaColor:

YellowShipping Port:

QingdaoLead Time:

20 working daysForging Automation Line Automatic Spray Graphite Machine

In the forging industry, automatic graphite spraying system for forging has become a necessary segment in the production of die forgings for the purpose of protecting dies and facilitating demoulding after metal forming. Now more and more die forging automatic spray graphite machines are replacing the original manual graphite spraying.

Compared with automatic graphite spraying operation, graphite spraying process is more arbitrary in manual operation, and the position and spraying amount of graphite emulsion are uneven every time. The parts that are sprayed less will be annealed and die-stuck while the parts that are sprayed more may lead to the temperature drop of forgings, which will affect the fluidity of forgings and lead to the situation that forgings are not fully filled.

Automatic graphite spraying machine can reduce forging cost. It can spray graphite emulsion more evenly and save graphite emulsion. Secondly, automatic graphite spraying replaces manual graphite spraying to liberate workers' labor force and reduce labor costs. With a few months' wages, you can buy a set of automatic graphite spray system that can be used for a long time.

Automatic Spray Graphite Machine Advantages gives :

1). Stable and accurate servo system control;

2). Replace manual operation to save labor cost;

3). Jet or graphite can be set up freely, working time can be adjusted;

4). The position of spraying is adjustable and easy to operate;

5). It can be customized according to customer site.